Description

Draws out moisture and keeps dry thermoforming sheets, to avoid the formation of pores.

Instrument drying.

Drying of plaster models, etc.

A recurring issue with dental thermoforming sheets is the accumulation of moisture. The type of plastic used in these products is porous in nature, and it is precisely in these pores where ambient moisture accumulates. Later, during the heating of the sheet, the moisture is transformed into water vapor and the pressure of this vapor stretches the material, generating bubbles. Although a well-sealed packaging can mitigate this unpleasant effect, experience shows that over time, moisture ends up penetrating, especially after the package of sheets has been unsealed.

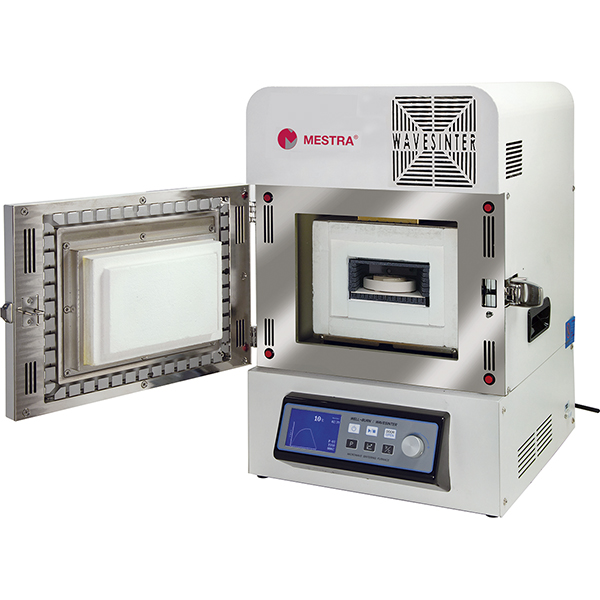

Unfortunately, there is no simple method that can eliminate moisture from contaminated plates, or keep the plate dry until use. The only reliable tool available on the market today is the MESTRA Drying Oven Ref. 080118.

The oven features a spacious chamber with six trays, which can accommodate a large amount of product.

The interior temperature is easily adjustable between 35-75 ºC, as well as the running time up to 24 hours, which gives the device a lot of flexibility in use.

An internal fan ensures a constant temperature throughout the chamber volume.

As it is constructed in stainless steel, clean up is very fast and easy. Due to the low temperature, its energy consumption is reduced.