Description

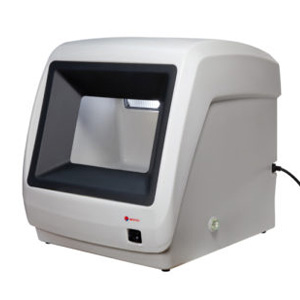

Box for spray application in zirconium processes.

Altamira cleaning chamber specially adapted for the application of the matting spray on models, prior to scanning.

The equipment requires an external suction (not included) that evacuates a strong flow of air from the inside of the chamber, preventing the spray from dirtying or contaminating the air in the work environment. It is also very useful for cleaning the metal dust left on the milling machine discs.

The suction power supply can be connected to the power socket located at the back of the box, so that they work in a synchronized manner.

|

Manufactured on a robust polypropylene frame, it has a large window that gives access to the chamber. All walls are smooth for easy cleaning. |

|

The device has a carefully designed deflector frame so that the steam stays inside the chamber, without leaks.

Lighting is another of the most carefully considered aspects: two powerful, low-consumption bulbs provide perfect lighting to the parts being vaporized, without the light ever shining directly into the eyes. Reflections and glare have also been eliminated. |

|

The double filter system has been the subject of a thorough study by our technicians. The design premises were accessibility, ease of cleaning and efficiency. The primary filter is located in the main chamber, so its access is immediate.

Cleaning and replacement are done without the use of any tools. Due to its concept, the filter can be cleaned and reused several times. It is also economical in case a replacement is required. |

|

Cleanliness, ergonomics and practicality at a reduced price is what the Mestra spray booth offers. Of course, with the usual level of quality and after-sales service of the MESTRA brand. |